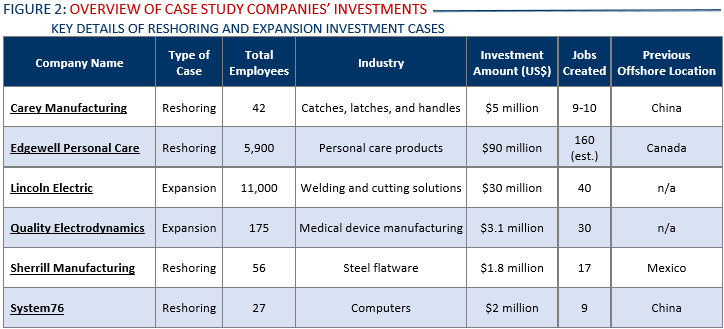

A CASE STUDY OF RESHORING AND EXPANDING IN THE UNITED STATES

Founded in 1981, Carey Manufacturing produces catches, latches, and handles in Cromwell, Connecticut – 15 miles south of Hartford. The company also owns and manufactures Amatom brand products, which include electronic hardware such as handles, standoffs, and spacers. Manufacturing space is shared with Floyd Manufacturing Co., Inc., a producer of precision automotive parts. Carey Manufacturing’s 30,000-square foot facility in Cromwell employs more than 40 people. In the early 2000s, the company outsourced the majority of its production to China in order to sell at prices comparable to its competitors. Starting in 2015, Carey Manufacturing started bringing production back to its facility in Cromwell. Since 2015, Carey Manufacturing has produced approximately 80 percent of its products in Cromwell.

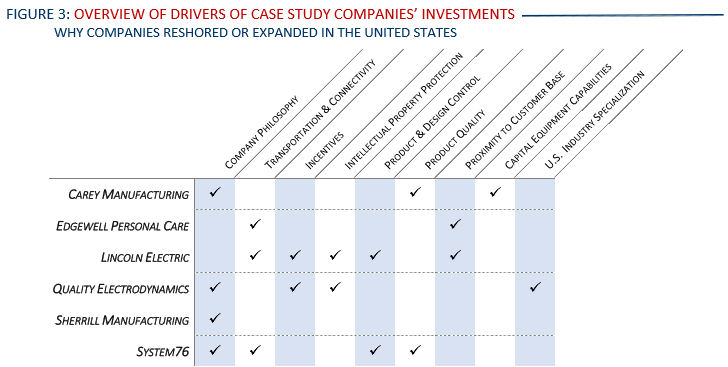

Altogether, Carey Manufacturing has invested nearly $5 million in equipment and other resources to reshore production thus far. The reshoring investment led to the creation of 10 new jobs. Carey Manufacturing began realizing that it could reshore production in a cost-effective way after being approached by the German-owned company TRUMPF in 2014. After seeing TRUMPF’s automated punch and laser cutting machinery, the company could envision itself manufacturing at a sufficient scale to keep costs low. TRUMPF’s North American subsidiary headquarters and manufacturing facility is located in nearby Farmington. The majority of Carey Manufacturing’s capital investment in reshoring went toward purchasing TRUMPF equipment manufactured in the United States and Germany. Ultimately, cost and company philosophy supporting manufacturing in the United States were driving factors in Carey Manufacturing’s decision to reshore. The reshoring process is still ongoing as the company adjusts to its new production capabilities.

Flexibility: With automated machinery and trained staff, Carey Manufacturing has the capability to customize and tailor its products to individual customer demands. In particular, their new machinery settings can be adjusted through a computer interface, which significantly reduces retooling times. With this level of flexibility, the company has more potential to develop additional pieces in its product line.

Proximity To Customers & Suppliers: Compared to a multi-month process of ordering parts from China, Carey Manufacturing is now able to deliver its products to consumers at a faster rate. Orders that once took approximately 18 to 26 weeks to manufacture and deliver from China can now be delivered in eight to ten weeks from Cromwell. The company is also able to efficiently modify orders based on customer requests. For example, when a customer needed a change for an existing part, Carey Manufacturing was able to prototype the new part, ship it to the client for testing, and then produce and ship the adjusted order, all within a week. With the majority of its manufacturing now taking place in the United States, it is easier for Carey Manufacturing to meet with local suppliers and customers, and the close proximity provides further business opportunities facilitated by in-person conversations.

Made In America: Manufacturing in the United States provides positive branding opportunities. According to Carey Manufacturing, multiple customers highly value a Made-in-the-U.S.A brand. For example, several potential buyers have expresses interest in purchasing certain products that are still produced in China once their manufacturing in reshored to the United States.

Establishing A Manufacturing Ecosystem: Carey Manufacturing had to relearn or create new systems upon bringing production back to the United States. Much of the manufacturing base that had existed in the area prior to the company’s outsourcing diminished by 2015. However, several engineers were still staffed or accessible in the Cromwell facility, which the company believes greatly enabled it to address this issue.

Financing: The costs of reshoring, particularly the costs associated with new capital equipment, were high. Carey Manufacturing expects to see a return on its investments starting in 2020 or 2021. The company perceives private banks as excessively risk averse, which reduces financial resources for small businesses who may require five to six years to see a return on investment.

Foreign Competitor Prices: Carey Manufacturing raised the prices of all its products by five percent in 2018 to compensate for higher costs, which the company associates with tariffs on steel. This is significant to the company as it has lost potential customers due to price differences of a few cents. Currently, China-based competitors have access to cold rolled steel at slightly lower prices than Carey Manufacturing.

Workforce Development: According to Carey Manufacturing, there is a lack of toolmakers between the ages of 35 to 55. This is notable to the company as younger staff lack significant relevant career experience. As many of its employees are nearing retirement age, the company worries about finding replacements for its pool of highly experienced workers. Carey Manufacturing perceives a past trend within the last couple generations where young adults entering the workforce were generally discouraged from entering the manufacturing industry. However, the company believes this trend has recently slowed or reversed and that local and state efforts are starting to address these issues.

There are several state and local workforce development and job placement programs near Cromwell, such as the Hartford Job Corps Academy and Our Piece of the Pie. In addition to taking advantage of these programs, Carey Manufacturing partners with local community colleges and other organizations, as well as hosts site visits for youth and other workforce development programs.

While Carey Manufacturing believes it could potentially benefit from available programs and incentives, it states that it lacks the time to research and learn about them. The company believes it could benefit from more effective communication of various program information.

Carey Manufacturing leadership admits that it does not know at this point if reshoring was the right choice for the firm. The company emphasizes that businesses undergoing similar projects should be patient because moving operations is not a quick or easy process. The company did not have a guide or example to follow and has instead been learning through trial and error, adding a significant amount of risk to the reshoring process.

“You take a huge risk because you do make every mistake in the book.”

Carey Manufacturing stresses the importance of thinking through the whole workflow process when establishing production, as manufacturing is complex and frequently presents unanticipated obstacles. Carey Manufacturing warns that not all small businesses are equipped to successfully reshore manufacturing. The company believes that with capable staff and the ability to purchase necessary equipment, it was uniquely positioned to bring back its production when it did.

This report was produced for review by SelectUSA, U.S. Department of Commerce. It was prepared by Ascendant Program Services, LLC, with Research Analysts Kimberly Aagaard, Veronica Faust, and Nicholas Hecker as the lead authors. 2019.